METRA

ORIGINS: Passion for Machining

Metra started as machinists more than 35 years ago, with the challenging job of setting up new parts in old brand multispindle machines. Today, we still keep this “philosophy” os a leading machining company, providing solutions to companies worldwide.

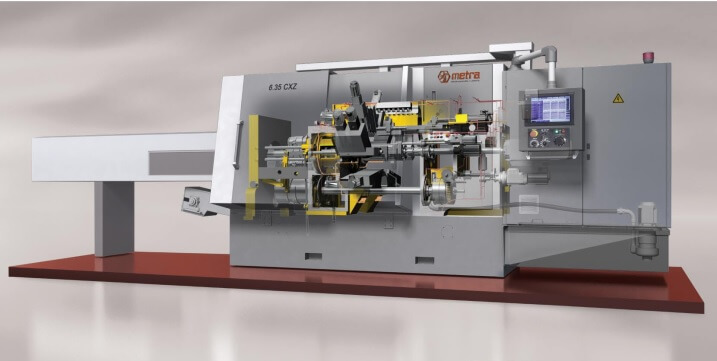

Faithful to our origins, METRA designs and builds multi-spindle automatic lathes easy to use as a solution to the production needs of medium-large series of precision machined parts.

FUNCTIONAL DESIGN

To obtain a safe machining process at maximum productivity, it’s essential to have a machine that can be operated as simple as possible.

In METRA, we design our machines under the functionality and operational principles, thinking mainly on the end-user, which is who will handle your daily production.

Complex machining concepts can sometimes make a machining process not reliable enough causing constant stops, high tooling costs and non-conforming parts.

UNLIMITED MACHINE CONFIGURATIONS

Connectivity for performance monitoring and remote assistance. Fully CNC & user friendly. Scalable confifiguration from 11 axis. Available in all models:

- In Spindle Stop versions, spindles stop at any station.

- Servo driven tool holders at any station.

- Spindle offsets at any station.

Minimum Confifiguration

- X axis slides

- RPM

- Indexing

- Servo Turret (T axis)

- CNC Subspindle (C6 + T6)

Minimum Confifiguration

- Indexing

- RPM

- 4 additional front slides (T2 to T5)

- Servo Turret (T axis)

- 5 XZ axis slides

- 2X axis cross slides (parting off + subspindle)

- CNC Subspindle (C6 + T6)

- C axis on every front slide